Wenesco Wave Solder Pots

One of Wenesco's most important product lines is Standard and Custom-made Wave Solder Pots for many commercial and industrial applications. We offer several options for varied applications, such as special nozzles and nitrogen inerting. Our wave solder pots will work with standard and lead-free solder.

Featured Here:

Standard Wave Pots, Custom Wave Pots, and Selective Solder Wave Pots.

All Standard Models include:

-

Ceramic coated interior for standard or lead free alloys to 600F.

-

Exterior housing is stainless steel with easy access to heaters.

-

Digital Thermostat displays current temperature and set point.

-

DC solder pump with smooth wave height control.

-

Safety circuit prevents motor starting before solder is melted.

-

A nozzle

(Above) Model M04 shown with optional nitrogen inerting covers.

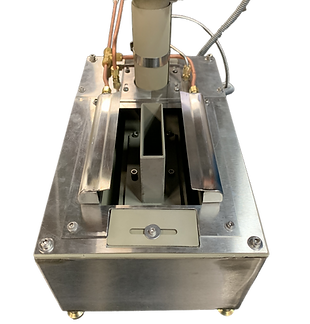

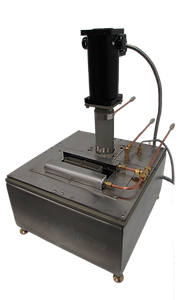

(Right/Left) Model M03 shown with standard remote control.

(Right/Left) Model M04 shown with standard remote control and custom nozzle.

(Right/Left) Model M03L Low Profile Wave Solder Pot is designed for use with automatic soldering systems, which require minimal vertical obstruction.

(Right/Left) Model M6 shown with optional nitrogen inerting system. Note the 6 x 1 inch nozzle is placed 90 degrees to the pump.

(Right/Left) Model M14 Wave Solder Pot shown with optional nitrogen inerting system.

Custom-built Wave Solder Pots:

For over 40 years, Wenesco has been developing wave solder pots for special applications, as well as replacing out-of-stock equipment made by others, including Dee, Hollis, Treiber, New Age, and Electrovert.

(Below) This Wave Solder Pot has a 42 X 12 inch wave surface and was made to apply lead-free solder to wires as they are fed from payout reels. Similar models were made for soldering truck radiators.

(Above) Custom Model M03 wave solder pot shown with auto slide, preheater, and fluxer.

Layout and details on Nitrogen Inerting Systems HERE

Foam & Wave Fluxers + Flux Stones HERE

Preheaters HERE

Return to directory of all Wenesco Solder Pots by clicking HERE